In the agricultural and textile industries, bale strapping is a crucial process that ensures the safe and efficient handling, transportation, and storage of products. Bale strapping refers to the application of straps or bands around bundles or bales of materials to secure them and prevent them from coming apart or shifting during various operations. This article explores the importance of bale strapping, its applications, materials used, and future trends in this field.

The Importance of Bale Strapping

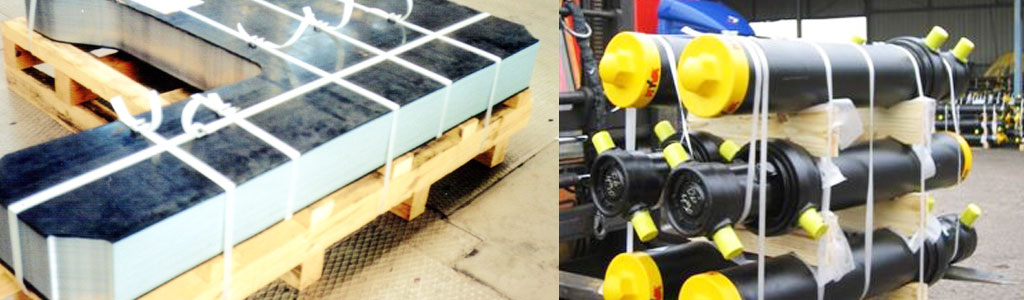

Bale strapping plays a vital role in maintaining the integrity of agricultural products such as cotton, hay, straw, and grain, as well as textile products like yarn and fabric. By securely fastening bundles, bale strapping reduces the risk of damage during handling, transportation, and storage. This not only preserves the quality of the products but also ensures their safety for consumers.

Moreover, bale strapping enhances the efficiency of logistics operations. Well-strapped bales are easier to load, unload, and stack, saving time and labor costs. They also occupy less space, allowing for more efficient use of transportation vehicles and storage facilities.

Applications of Bale Strapping

Bale strapping is widely used in various agricultural and textile processes. In the agricultural sector, it is commonly employed for harvesting and storing crops such as cotton, hay, straw, and grain. Bale strapping ensures that these crops are securely bundled for transportation to storage facilities or processing plants.

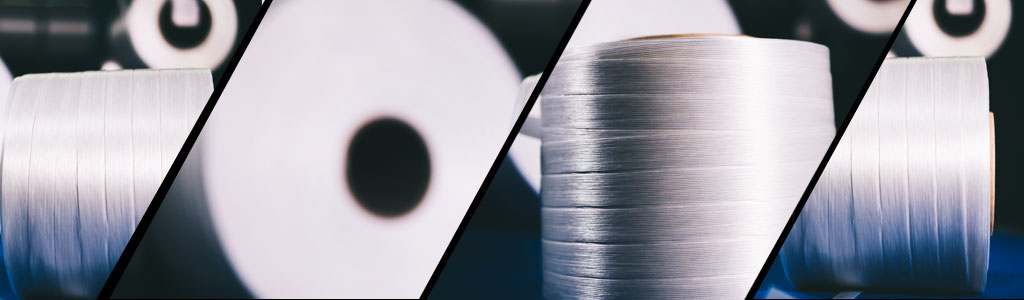

In the textile industry, bale strapping is essential for handling yarn, fabric, and other textile materials. Yarn bales are strapped together to prevent tangling and ensure smooth processing. Fabric bales are also strapped to maintain their shape and integrity during shipping and storage.

Materials Used for Bale Strapping

A variety of materials are used for bale strapping, depending on the specific application and requirements. Some of the commonly used materials include:

1.Polypropylene Straps: Polypropylene is a strong, lightweight, and cost-effective material widely used for bale strapping. It offers good tensile strength and resistance to abrasion and weathering.

2.Polyester Straps: Polyester straps are stronger and more durable than polypropylene and are often used for heavier loads. They are also resistant to chemicals and UV radiation.

3.Steel Straps: Steel straps are the strongest option and are suitable for securing very heavy loads. However, they are heavier and less flexible than other materials.

4.Natural Materials: In some cases, natural materials like hemp or jute are used for bale strapping. These materials are biodegradable and environmentally friendly but may not offer the same strength and durability as synthetic materials.

Techniques and Equipment for Bale Strapping

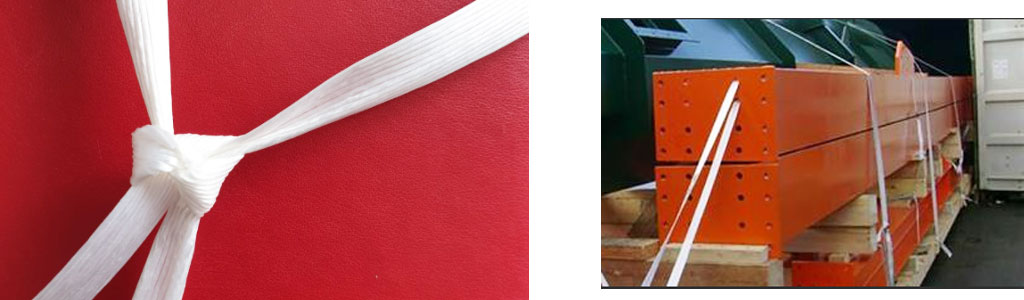

Bale strapping can be done manually or using specialized equipment. Manual strapping involves using a strap tensioner and sealer to apply and secure the straps around the bale. However, for larger and heavier bales, automated strapping machines are often used.

Automated strapping machines can significantly increase the efficiency and speed of bale strapping. These machines use pneumatic or electric motors to tension and secure the straps around the bale, reducing the need for manual labor. Some advanced machines also have sensors and automatic adjustment features to ensure consistent and reliable strapping.

Future Trends in Bale Strapping

With the advancement of technology, we can expect to see several innovations in bale strapping in the future. One such trend is the use of smart strapping systems that integrate sensors and data collection capabilities. These systems can monitor the tension and condition of the straps, providing valuable insights that can be used to optimize strapping operations and ensure the safety of the bales.

Another trend is the development of more environmentally friendly strapping materials. With the increasing awareness of environmental issues, manufacturers are exploring the use of recyclable and biodegradable materials for bale strapping. This not only reduces waste but also aligns with the sustainability goals of many agricultural and textile companies.

In conclusion, bale strapping plays a crucial role in maintaining the integrity and efficiency of agricultural and textile products. With the continuous development of new materials, techniques, and equipment, we can expect to see further improvements in bale strapping that will enhance the safety, quality, and sustainability of these industries.