Cord strapping, often referred to as polyester cord strapping, is a robust and versatile packaging material used extensively across various industries to secure and bundle products for transportation and storage. This article explores the fundamental aspects of cord strapping, including its composition, applications, benefits, and considerations for use.

What is Cord Strapping?

Cord strapping is a type of synthetic strapping made from polyester fibers that are woven together to create a high-strength, flexible material. Unlike traditional steel strapping, cord strapping combines the resilience and flexibility of synthetic materials with the structural integrity needed for secure packaging. It is typically used in conjunction with strapping tools and buckles or seals to ensure a tight and reliable hold.

Composition and Manufacturing

The manufacturing process of cord strapping involves several key steps:

1. Fiber Selection: High-quality polyester fibers are selected for their strength and durability. These fibers are chosen for their resistance to abrasion, moisture, and UV degradation.

2. Weaving: The polyester fibers are woven into a cord-like structure, which provides the strapping with its strength and flexibility. This weaving process can be adjusted to produce strapping of various thicknesses and strengths.

3. Coating: To enhance performance, the woven cord is often coated with a polymer layer. This coating provides additional protection against environmental factors and improves the strapping's ability to grip and hold.

Key Features of Cord Strapping

1. Strength and Durability: Cord strapping is known for its high tensile strength, which allows it to secure heavy loads effectively. The polyester fibers used in cord strapping are designed to withstand significant stress without breaking or deforming.

2. Flexibility: Unlike steel strapping, cord strapping is flexible and can conform to the shape of the packaged goods. This flexibility reduces the risk of damage to the products and ensures a snug fit around irregularly shaped items.

3. Resistance to Environmental Factors: Polyester cord strapping is resistant to moisture, chemicals, and UV rays. This makes it suitable for use in various environments, including those with high humidity or exposure to sunlight.

4. Ease of Handling: Cord strapping is lightweight and easier to handle compared to steel strapping. It is less likely to cause injury during application, and the absence of sharp edges reduces the risk of accidents.

Applications of Cord Strapping

Cord strapping is used in a wide range of applications, including:

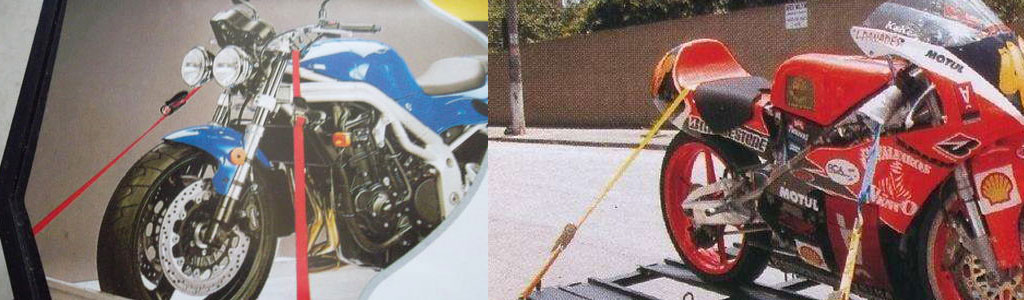

1. Logistics and Transportation: In the logistics industry, cord strapping is employed to secure goods on pallets, containers, and shipping crates. It helps prevent shifting and damage during transit, ensuring that products arrive at their destination in good condition.

2. Construction and Manufacturing: Cord strapping is used to bundle construction materials, such as lumber, pipes, and metal products. Its strength and durability make it ideal for holding heavy or bulky items together.

3. Agriculture: In agriculture, cord strapping is used to secure bales of hay, straw, and other agricultural products. Its ability to withstand outdoor conditions makes it a preferred choice for securing these items.

4. Recycling: Cord strapping is used to bundle recyclable materials, such as paper, cardboard, and plastics. The strapping helps to keep the materials compact and manageable for processing and transportation.

Benefits of Cord Strapping

1. Cost-Effectiveness: Compared to steel strapping, cord strapping is often more affordable. Its lower cost, combined with its effectiveness, makes it a popular choice for many industries.

2. Safety: The absence of sharp edges and the flexibility of cord strapping contribute to a safer working environment. Workers are less likely to experience injuries when handling cord strapping compared to steel alternatives.

3. Versatility: Cord strapping can be used for a variety of applications, from securing light packages to bundling heavy construction materials. Its versatility makes it a valuable tool in many sectors.

4. Environmental Impact: Polyester cord strapping is generally recyclable, which reduces its environmental impact. Many manufacturers offer recycling programs for used strapping materials, contributing to sustainability efforts.

Considerations for Use

1. Proper Tensioning: Ensuring the correct tension is crucial for effective strapping. Over-tensioning can damage the products being secured, while under-tensioning can result in inadequate security.

2. Compatibility with Tools: Cord strapping requires specific tools for application, such as tensioners, sealers, and cutters. It is important to use the correct tools to achieve a secure and reliable hold.

3. Storage Conditions: While cord strapping is resistant to many environmental factors, it should be stored in a dry, cool place to maintain its effectiveness. Prolonged exposure to extreme conditions can affect its performance.

4. Maintenance and Inspection: Regular inspection of cord strapping and associated tools is necessary to ensure they remain in good condition. Worn or damaged strapping should be replaced promptly to maintain security.

Conclusion

Cord strapping is a versatile, durable, and cost-effective solution for securing and bundling products across various industries. Its combination of strength, flexibility, and resistance to environmental factors makes it a valuable asset in logistics, construction, agriculture, and recycling. By understanding its composition, applications, and benefits, businesses can make informed decisions about incorporating cord strapping into their packaging and transportation processes. Proper handling, tensioning, and maintenance of cord strapping ensure that it delivers reliable performance and contributes to the efficient and safe management of goods.