In today's world of evolving technologies and materials, composite straps have emerged as a reliable and efficient solution for a wide range of applications. From heavy-duty industrial uses to lightweight consumer products, composite straps have proven their worth in terms of durability, strength, and adaptability. This article delves into the intricacies of composite straps, exploring their composition, advantages, and the various industries they serve.

Composition and Manufacturing of Composite Straps

Composite straps are typically composed of two or more materials, often with one serving as a reinforcement (such as fiberglass, carbon fiber, or Kevlar) and the other as a matrix (such as a polymer resin). The reinforcement materials provide strength and stiffness, while the matrix holds the reinforcements together and transmits loads between them. The manufacturing process of composite straps often involves layering the reinforcement materials with the matrix material, followed by curing or hardening to create a strong, lightweight composite.

Advantages of Composite Straps

One of the key advantages of composite straps is their exceptional strength-to-weight ratio. Composite materials can achieve much higher strength and stiffness than traditional materials like steel or aluminum, while weighing significantly less. This makes composite straps ideal for applications where weight reduction is crucial, such as in aerospace, automotive, and sporting goods.

Another advantage of composite straps is their resistance to corrosion and chemical attack. Unlike metals, composite materials are not susceptible to rust or oxidation, and they can withstand exposure to harsh environments and chemicals. This makes composite straps an excellent choice for outdoor equipment, marine applications, and other environments where corrosion is a concern.

Additionally, composite straps offer design flexibility. The ability to tailor the material properties and layout of the reinforcements allows for the creation of customized solutions that meet specific performance requirements. This flexibility makes composite straps suitable for a wide range of applications, from load-bearing structures to decorative accessories.

Applications of Composite Straps

Composite straps find numerous applications across various industries. In the aerospace industry, composite straps are used in aircraft construction to provide structural reinforcement while minimizing weight. They are also used in aerospace equipment such as parachutes and aircraft harnesses, where their lightweight yet robust properties are crucial.

In the automotive industry, composite straps are increasingly being used in lightweight vehicle design. They are employed in chassis components, suspension systems, and body panels, helping to reduce overall vehicle weight and improve fuel efficiency.

Composite straps also have a significant role in the sporting goods industry. They are used in equipment such as snowboard bindings, ski boots, and bicycle frames, where their high strength-to-weight ratio and resistance to wear and tear are advantageous.

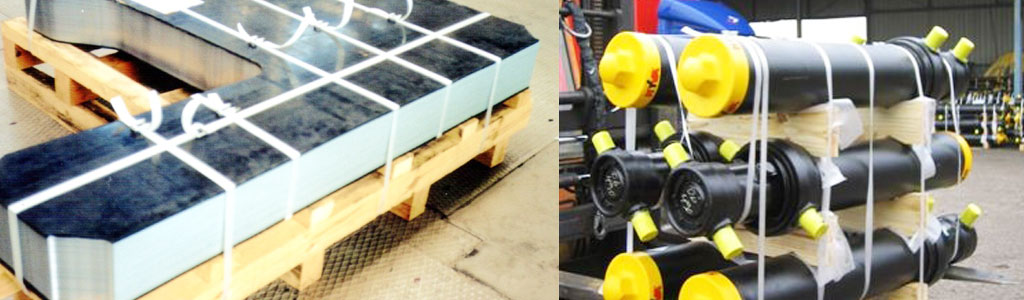

Furthermore, composite straps have applications in packaging, shipping, and logistics. They are used as tie-down straps for securing cargo, as well as in strapping systems for bundling and packaging products. Their durability and resistance to stretching make them a reliable choice for these applications.

Environmental Considerations

While composite straps offer numerous benefits, there are also environmental considerations to take into account. The production of composite materials requires energy and resources, and the disposal of composite waste can be challenging. However, advances in recycling and repurposing composite materials are ongoing, and the industry is working towards more sustainable solutions.

Conclusion

Composite straps have revolutionized many industries by providing a lightweight, strong, and durable alternative to traditional materials. Their exceptional strength-to-weight ratio, resistance to corrosion, and design flexibility make them suitable for a wide range of applications. As technology continues to evolve and new composite materials are developed, we can expect to see composite straps playing an even more significant role in the future.