In the intricate dance of modern industrial processes, waste recycling stands as a pivotal figure, orchestrating the transition from disposal to resource reutilization. As environmental consciousness escalates globally, the efficiency and security of recycling operations have become paramount. Among the myriad tools facilitating this transformation, baler strapping emerges as a cornerstone, ensuring that waste materials are compacted, secured, and ready for sustainable repurposing. This article delves into the mechanisms by which baler strapping enhances the waste recycling process, focusing on its contributions to security, efficiency, and overall operational excellence.

The Role of Balers in Recycling

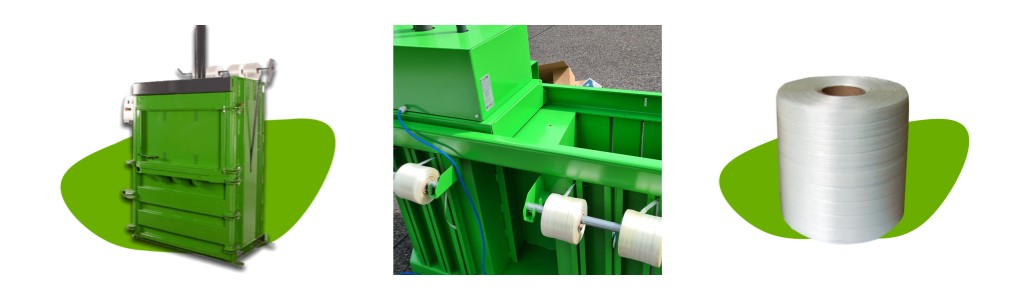

Baler machines are indispensable in the recycling industry, tasked with compressing various types of waste materials into manageable, dense blocks or bundles. These materials range from cardboard, plastic bottles, and metal scraps to organic waste and electronic waste (e-waste). By reducing the volume of waste, balers facilitate easier handling, transportation, and storage, thereby cutting down costs and environmental impact.

However, the effectiveness of baling alone is insufficient without adequate strapping solutions. Baler strapping serves as the binding agent, securing the compressed waste bundles to prevent them from loosening or unraveling during transit. This critical function not only preserves the integrity of the recycled materials but also enhances safety by minimizing the risk of accidents caused by unstable loads.

Ensuring Security: The Importance of Durable Strapping

The security aspect of waste recycling processes cannot be overstated. Baler strapping must possess certain qualities to fulfill its role effectively:

1.Strength and Durability: High-tensile strength strapping ensures that even the heaviest and most irregularly shaped waste bundles remain intact. Polyester, polypropylene, and steel strapping are commonly used due to their robust nature, capable of withstanding the pressures of transportation and handling without breaking.

2.Weather Resistance: Exposure to varying weather conditions is inevitable in outdoor recycling facilities. Strapping materials that resist moisture, UV degradation, and temperature fluctuations maintain their integrity over time, preventing premature failure.

3.Ease of Application: Automated strapping systems streamline the process, reducing human error and increasing productivity. These systems often incorporate features like tension control and sealing mechanisms that guarantee consistent and secure bunding.

By incorporating these attributes, baler strapping significantly reduces the likelihood of waste spills or accidents, thereby safeguarding both personnel and infrastructure.

Boosting Efficiency: From Waste to Resource Quickly

Efficiency is another cornerstone of successful recycling operations. Baler strapping plays a pivotal role in accelerating the transition from waste collection to market-ready recycled materials:

1.Optimized Loading: Securely strapped bundles allow for more efficient loading onto trucks and ships, maximizing payload capacity without compromising safety. This reduces the number of trips required, cutting down transportation costs and carbon emissions.

2.Reduced Downtime: High-quality strapping reduces the need for frequent replacements due to breakage or wear. This minimizes equipment downtime and maintenance requirements, enabling recycling facilities to operate more continuously and productively.

3.Preparedness for Sorting and Processing: Properly bundled waste facilitates more accurate sorting, as bundles maintain their shape and composition throughout the recycling line. This enhances the quality of the final recycled products, making them more marketable and valuable.

Innovation in Baler Strapping Technology

The evolution of baler strapping technology further amplifies its benefits. Advances in materials science have led to the development of biodegradable and recyclable strapping options, aligning with the circular economy principles. These eco-friendly alternatives reduce the environmental footprint of the recycling process itself, fostering a more sustainable cycle.

Moreover, intelligent automation systems are integrating sensors and IoT technology to monitor strapping tension, detect defects, and optimize strapping consumption in real-time. Such innovations not only enhance the precision and reliability of strapping applications but also contribute to data-driven decision-making, further optimizing recycling operations.

Conclusion

In the grand tapestry of waste recycling, baler strapping is a vital thread that binds efficiency and security together. By ensuring that waste materials are securely bundled, transported, and processed, strapping solutions facilitate smoother, safer, and more environmentally friendly recycling processes. As technology continues to advance, the role of baler strapping will undoubtedly evolve, further enhancing its contributions to the circular economy. By embracing these innovations and prioritizing high-quality strapping practices, the recycling industry can look forward to a future where waste is transformed into valuable resources with unprecedented efficiency and sustainability.