Abstract:

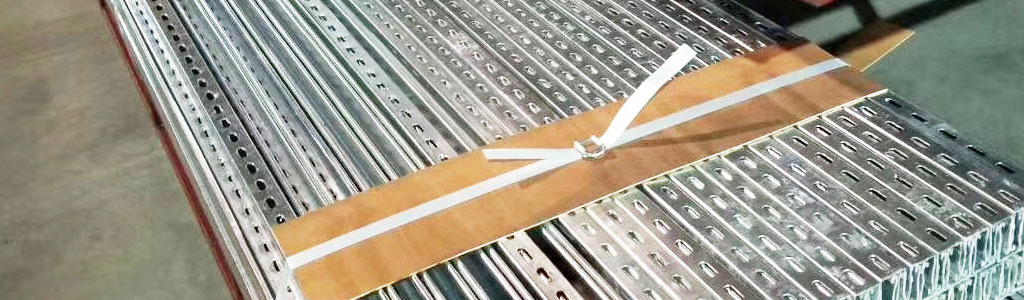

Polyester composite straps are versatile materials that have found widespread applications across various industries due to their exceptional strength, durability, and lightweight nature. This article explores the innovative designs and applications of polyester composite straps, highlighting their unique characteristics and the advantages they offer over traditional materials.

Introduction:

Polyester composite straps have emerged as a preferred choice for numerous industries due to their unparalleled performance and adaptability. These straps are made from a combination of polyester fibers and other materials, resulting in a strong, lightweight, and durable product. This article aims to delve into the innovative designs and applications of polyester composite straps, examining their structure, properties, and the benefits they offer in various industries.

Innovative Designs:

1. Fiber Architecture: Polyester composite straps are designed with a unique fiber architecture that enhances their strength and durability. The fibers are arranged in a specific pattern, such as unidirectional or bidirectional, to optimize their performance under different load conditions.

2. Hybrid Composite Materials: Polyester composite straps can be combined with other materials, such as carbon fibers or glass fibers, to create hybrid composite materials. This innovative design approach allows for the development of straps with enhanced properties, tailored to specific applications.

3. Coating and Surface Treatments: Polyester composite straps can be coated or surface-treated with various materials to improve their performance and adaptability. For instance, anti-abrasion coatings can be applied to increase the straps' wear resistantproperties, while UV-resistant coatings can enhance their durability in outdoor applications.

Applications:

1. Aerospace Industry: Polyester composite straps are widely used in the aerospace industry due to their lightweight nature and high strength-to-weight ratio. They are employed in the construction of aircraft components, such as wings and fuselages, as well as for securing cargo during transportation.

2. Automotive Industry: Polyester composite straps are used in the automotive industry for various applications, including seat belts, airbags, and structural components. Their high tensile strength and durability make them an ideal choice for these critical safety features.

3. Construction Industry: Polyester composite straps are employed in the construction industry for reinforcing concrete structures, such as bridges and buildings. Their high strength and flexibility enable them to withstand the harsh environmental conditions and heavy loads encountered in these applications.

4. Sports and Leisure: Polyester composite straps are used in a range of sports and leisure equipment, such as bicycle frames, golf club shafts, and fishing rods. Their lightweight nature and high strength make them an ideal choice for these applications, enabling improved performance and durability.

Conclusion:

Polyester composite straps have emerged as a versatile and innovative material, finding widespread applications across various industries. Their unique characteristics, such as high strength, durability, and lightweight nature, offer numerous advantages over traditional materials. This article has explored the innovative designs and applications of polyester composite straps, highlighting their adaptability and the benefits they offer in diverse fields. As research and development continue, it is expected that polyester composite straps will continue to play a significant role in shaping the future of materials science and engineering.