A Sustainable Solution for Eco-Friendly Waste Management

Introduction

Hot melt strapping, also known as heat seal strapping, is a type of packaging material that is increasingly being used in waste packaging. This innovative technology offers numerous benefits, such as reduced waste, increased efficiency, and improved safety. This article will discuss the uses of hot melt strapping in waste packaging, its advantages, and the potential impact it has on the future of waste management.

Uses of Hot Melt Strapping in Waste Packaging

Hot melt strapping is used in various waste packaging applications, including:

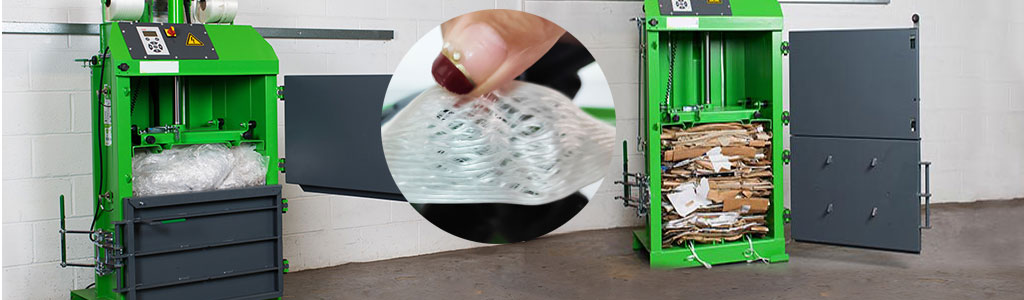

1. Solid waste collection and disposal: Hot melt strapping is used to secure waste bags, ensuring that they do not leak or tear during transportation and disposal. This prevents the spread of harmful bacteria and contaminants, as well as reduces odors.

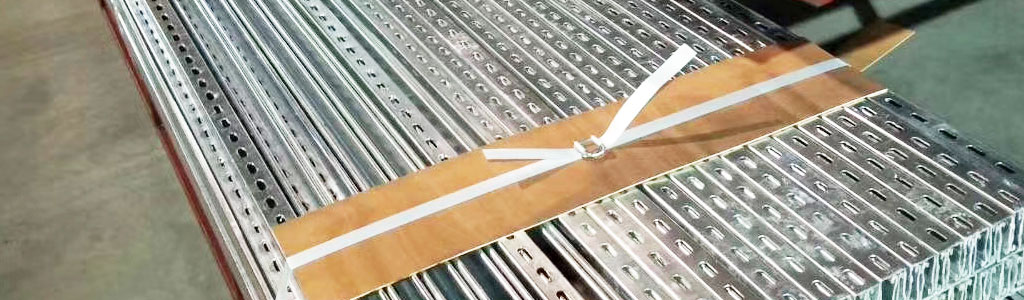

2. Recycling: Hot melt strapping is used to band recyclable materials, such as paper, plastic, and metal, for easier handling and transportation. This helps to reduce waste and improve the efficiency of recycling operations.

3. Hazardous waste disposal: Hot melt strapping is used to secure hazardous waste containers, ensuring that they remain sealed during transportation and disposal. This minimizes the risk of accidental spills and exposure to harmful substances.

Advantages of Hot Melt Strapping in Waste Packaging

Hot melt strapping offers several advantages over traditional packaging methods, including:

1. Sustainability: Hot melt strapping is made from polypropylene, a recyclable material. This makes it a more environmentally friendly option compared to traditional strapping materials, such as steel or plastic.

2. Cost-effectiveness: Hot melt strapping is a more cost-effective option compared to traditional strapping methods, as it requires less material and energy to produce.

3. Strength and durability: Hot melt strapping is stronger and more durable than traditional strapping materials, making it ideal for securing heavy or bulky waste.

4. Ease of use: Hot melt strapping is easy to apply and secure, reducing the time and effort required for waste packaging.

5. Safety: Hot melt strapping helps to prevent accidents and injuries by securing waste materials, reducing the risk of spills and exposure to harmful substances.

The Future of Waste Management with Hot Melt Strapping

As concerns about environmental sustainability continue to grow, hot melt strapping is poised to play an increasingly important role in waste management. Its numerous advantages, including sustainability, cost-effectiveness, strength, and ease of use, make it an attractive alternative to traditional packaging methods.

In conclusion, hot melt strapping offers a sustainable solution for waste packaging, with numerous benefits for both the environment and waste management operations. As awareness of the need for more eco-friendly waste management practices grows, hot melt strapping is likely to become an increasingly popular choice for waste packaging applications.

BSTSTRAP

Whatsapp:+86 186 5722 7862

E-mail:claire@bststrap.com